Product Lifecycle Assessment Shows True Environmental Impact

By Marianne Santangelo | June 14, 2011

Category:

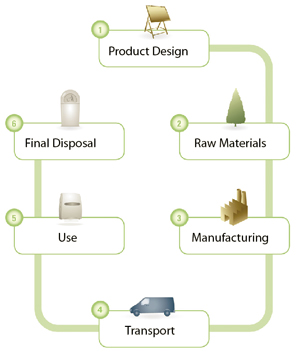

The cradle-to-grave approach of looking at a product’s life cycle comprises six stages, all of which must be assessed to determine true environmental impact.

Recent and continuing global developments have accentuated the need for manufacturers to become more environmentally conscious. As markets develop worldwide, the pressure on natural resources intensifies as well. This, coupled with global economic conditions and a consumer-driven focus on the environment, is causing manufacturers to consider a bigger-picture approach to sustainability.

For many manufacturers, following environmentally sustainable practices is not only the right thing to do for the future; it has become a business imperative—part of the “triple bottom line” comprising economic dimensions (profits) as well as environmental and social dimensions. In fact, sustainable business practices can provide tangible opportunities and benefits for manufacturers:

- Reduced operating costs from improved operational efficiencies and lower energy and raw material use

- Competitive advantages from developing more sustainable products that meet or exceed customer expectations

- Reduced exposure to risk by anticipating and managing or avoiding events that could increase costs, reduce market share, or damage reputation

- Motivated employees and greater interest from prospective employees who want their employers to invest in a sustainable global future

Life Cycle Mindset

Every activity a manufacturer performs has a social, economic, and environmental impact. Often these impacts are not unearthed until someone examines the complete life cycle of a product. When a manufacturer performs this analysis, it learns that an environmentally sustainable product is not just one that uses the most recycled content or that can itself be recycled. Focusing on a “100 percent recycled” concept alone does not capture the true environmental picture. Instead, an environmentally sustainable product is made, used, and disposed of in ways that can lower the overall impact on the environment.

Life cycle assessments are data-intensive. Data may be required for such elements as raw materials; chemicals, fertilizers, and pesticides; energy; physical inputs such as water; emissions into air, water, and soil; products and co-products (process outputs that have value and are not treated as wastes, such as industrial scrap); solid waste; and wastewater. It also is important for manufacturers to look at their suppliers’ data.

The EPA suggests that a life cycle assessment also helps manufacturers avoid simply shifting the environmental burden from one process to another. For example, when selecting between two rival products, end users may think that Product 1 is better for the environment because it generates less solid waste than Product 2. However, after a life cycle assessment is performed, it might be determined that Product 1 actually creates larger cradle-to-grave environmental impacts when measured across air, water, and land. It may cause more chemical emissions during the manufacturing stage. Therefore, Product 2, which produces solid waste, may be viewed as producing less cradle-to-grave environmental harm than Product 1 because of its lower chemical emissions.

One tool manufacturers can use to analyze their sustainability is the product life cycle assessment, which the U.S. Environmental Protection Agency (EPA) considers a cradle-to-grave approach. This cradle-to-grave approach begins with gathering raw materials from the earth to create the product and ends when all materials are returned to the earth. Thinking about the product life cycle helps manufacturers see the whole picture by actively and systematically charting each stage of a product’s life (see lead image):

1. Product Design

1. Product Design

Designing products that reduce consumption across their entire life is the first step in the cradle-to-grave approach.

The product design stage has the greatest influence on a product’s life cycle and environmental impact. That is why environmental stewardship must be an integral part of the development process, on par with cost, quality, and manufacturing.

Those involved in the process should look beyond the features and functionality of a product to also consider its raw materials, packaging formats and materials, and transportation efficiencies to identify sustainable opportunities in all of these areas.

2. Raw Materials

2. Raw Materials

A product’s life cycle begins with the removal of raw materials and energy sources from the earth. Therefore, the second step is to responsibly and sustainably source the raw materials used in product production. Harvesting trees and mining nonrenewable materials are examples of raw-materials acquisition. Transporting these materials from the point of acquisition to the point of processing also is included in this stage.

Reducing raw-material usage and increasing sustainable sourcing are not limited just to the product itself. These practices also should be applied to product packaging. For example, a manufacturer could recycle or repurpose containers or fibers as packaging materials instead of using new materials.

3. Manufacturing

3. Manufacturing

During the manufacturing stage, raw materials are transformed into a product or package.

In sustainable manufacturing, the goal is to limit the amount of natural resources consumed, including energy and water, to make a product while managing the facility and its equipment to generate the least amount of waste and greenhouse gas emissions possible. One strategy is to recycle the waste heat generated from the manufacturing process to power that process. Innovative manufacturing technologies also may help to reduce the amount of raw materials needed to manufacture a product.

4. Transportation

4. Transportation

The fourth step involves developing more efficient ways to pack, handle, and transport products to reduce distribution’s impact. Which mode of transportation to use to distribute products, the fuel efficiency of those vehicles (and their resulting greenhouse gas emissions), and the locations of facilities through which product moves on its way to market all affect a product’s environmental footprint.

Improved product packaging also can reduce transportation’s impact. Innovative packaging can mean fitting more product into a box, more boxes into a case, more cases onto a pallet, and more pallets onto a truck, thus putting fewer trucks on the road and reducing greenhouse gas emissions.

5. Use

5. Use

This stage focuses on improving product performance to reduce waste. It is the consumer’s or user’s actual use, reuse, and maintenance of the product. Once the product is distributed, all activities associated with the useful life of the product are part of this stage. This includes energy demands and environmental wastes from both product storage and consumption. Some products or materials may need to be reconditioned, repaired, or serviced to maintain their performance.

Prudent product manufacturers study real-world product usage to explore how different product formats, manufacturing technologies, raw-materials mixes, and even packaging or dispensing systems can affect the quantity of product used and how much goes to waste.

6. Disposal

6. Disposal

The disposal stage includes the energy requirements and environmental wastes associated with product or material disposal.

A vital part of sustainability performance and a key component of a product’s life cycle is reducing the amount of product and product packaging destined for landfill disposal. In some cases, this may mean reusing or repurposing products. In other cases, it may mean recycling or “upcycling,” converting waste into a secondary material, such as turning plastic bags into knitting yarns.

Sustainability Can Lead to Better Business

By applying life cycle thinking, manufacturers can consider the environmental impacts of a product throughout its entire life—from initial design to final disposal. Improvements to the various stages of the product life cycle assessment can serve to make a company more competitive in the long run. In addition, manufacturers that undertake sustainability as a corporate goal may find themselves better positioned to face more stringent environmental regulations.

Additional Benefits of a Product Life Cycle Assessment

A product life cycle assessment can provide further benefits to manufacturers by helping them to:

- Align policies and decisions with business goals based on sound scientific evidence

- Inform the strategies and action plans of various business groups within a company

- Evaluate the environmental risks and benefits of new product designs

- Identify the best opportunities for product innovation and improvement

The assessment also can assist manufacturers on the road to sustainability by helping them to understand the human health and environmental impacts of the products manufactured. This technique involves:

- Compiling an inventory of relevant material and energy inputs and releases

- Evaluating potential environmental impacts associated with inputs and releases

- Interpreting the results to help product purchasers to make informed decisions

Side by side, we move metal fabrication forward.

FMA unites thousands of metal fabrication and manufacturing professionals around a common purpose: to shape the future of our industry, and in turn shape the world.

Learn More About FMA